Inventory management is the process of documenting and accounting for all the equipment, materials, parts, tools, or goods your business oversees daily. This essential process has a direct impact on productivity and profitability; it significantly affects the customer experience. Inaccurate stock of what’s in your warehouse. on your trucks, at job sites, etc., results in an inability to deliver on customer requests and work orders.

The two primary methods to conduct inventory management are manually (with physical items like pen and paper) and digitally (with software tools). In this blog post, we’ll examine key differences between physical and digital inventory management methods.

Physical Inventory Management

Physical inventory management involves manually writing down serial numbers and keeping an accurate count of all the resources in your warehouse, trucks, job sites, etc. With a clipboard in hand, employees physically “take inventory” by noting whether a needed item is in stock, unfit for use, missing, or ready for usage.

The disadvantages of physical inventory management largely center around the amount of time to complete the task and the level of accuracy. This approach takes employees longer to carry out (by requiring them to write down detailed notes, transcribe serial numbers, or provide other information by hand). As a result, productivity is negatively impacted, and many inaccuracies can occur. Error-filled checklists and subsequent rework can waste valuable time and company resources, or falsely indicate that items are in stock or on-hand.

Digital Inventory Management

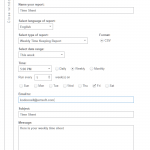

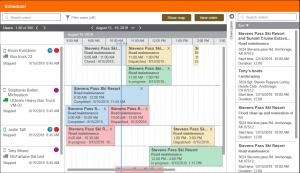

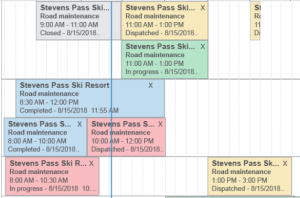

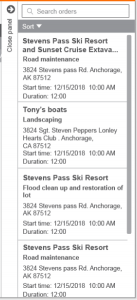

Digital inventory management uses technology to support an organization’s processes. This method revolutionizes workflows for employees by enabling them to use mobile devices and apps to complete their digital checklists. Digital inventory management tools and techniques involve either smartphone or tablet devices loaded with software and mobile apps to scan SKUs, bar codes, and complete electronic forms.

Making the transition from physical to digital inventory management positively impacts your organization’s productivity and profitability. Advantages of digital inventory management over physical inventory management include:

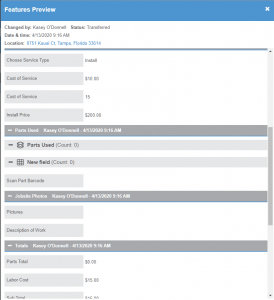

- Reduced errors from automatically scanning inventory barcodes via mobile device cameras.

- Faster completion times (with no manual transcription of information on paper).

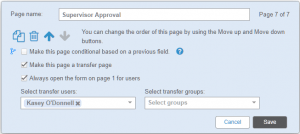

- Streamlined workflows, as supervisors can receive & review completed electronic forms immediately.

- Less shrinkage, with parts, tools, or goods able to be quickly accounted at any time and at any location.

- Enhanced customer satisfaction as a result of reliable and consistent service.

Now that each of these inventory methods have been defined and the clear advantages of digital inventory management have been outlined, let’s take a closer look at the details with a direct analysis of the two.

Comparison of Physical and Digital Inventory Management

When compared head-to-head, digital inventory management trumps outdated physical inventory management:

Precision and speed: Digital inventory management offers a more accurate and faster alternative to paperwork. By automating several portions of the process (like adding serial numbers, sending information for approval, and calculating totals), employees will have more time to complete additional tasks after quickly taking inventory.

Scalability and versatility: Instead of having to erase or scratch out faulty information on paper inventory sheets, a simple edit of a digital form field can relieve headaches and confusion for your office staff. The intuitive design of digital inventory management tools also makes it easy for all your teams to ramp up quickly on the method.

Cost and simplicity of use: High shrinkage, slow and long inventory processes, and a steep learning curve can be detrimental to your bottom line. Electronic inventory is easier and more cost-effective for your business.

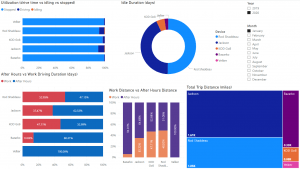

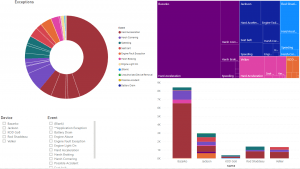

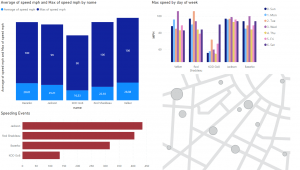

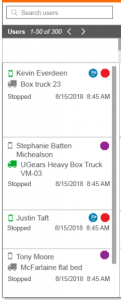

Real-time tracking and reporting: A final category where digital inventory management wins is collecting and visualizing important data quickly. Digital tools allow administrators to view a comprehensive dashboard of all inventory counts on-demand. As a result, business leaders can make smarter operational decisions.

Schedule a free, personalized demo today if you’d like to see how Actsoft’s flagship software, TeamWherx® can enhance your inventory management processes and boost productivity and profitability.

Share this post:

About the author : Andrew Forest

Drew Forest is a writer, marketer, and content creator. He enjoys traveling, fantasy football, and watching Tampa Bay sports teams win championships.

Encore & Geotab Drive

Encore & Geotab Drive

Gain even greater insight into the daily activities of your fleet using the combination of Geotab and Actsoft. Geotab devices provide detailed data collection and seamless integration with our solutions; learn more about the ways your vehicles are being used daily with the power of this tandem.

Gain even greater insight into the daily activities of your fleet using the combination of Geotab and Actsoft. Geotab devices provide detailed data collection and seamless integration with our solutions; learn more about the ways your vehicles are being used daily with the power of this tandem.

Actsoft partnered with Odin to provide our solutions overseas, through payment processing integrations. Odin helps us support user management for our software; customers can also purchase our products through Odin’s billing platform.

Actsoft partnered with Odin to provide our solutions overseas, through payment processing integrations. Odin helps us support user management for our software; customers can also purchase our products through Odin’s billing platform.

VisTracks powers our Electronic Logging Device (ELD) solution, which enables transportation businesses to easily automate their hours of service logs, remain in governmental compliance, and reduce their potential to incur costly fines.

VisTracks powers our Electronic Logging Device (ELD) solution, which enables transportation businesses to easily automate their hours of service logs, remain in governmental compliance, and reduce their potential to incur costly fines. Integration between Actsoft solutions and BeWhere’s software products is available. Take your team’s asset tracking, cellular data connectivity, and field insight a step further with effective, cross-application compatibility.

Integration between Actsoft solutions and BeWhere’s software products is available. Take your team’s asset tracking, cellular data connectivity, and field insight a step further with effective, cross-application compatibility.

CalAmp tracking devices for vehicles and assets alike are compatible with Actsoft solutions, making it easy for you to efficiently monitor your equipment and fleet cars. Help your team enhance accountability, safety, and savings through a combination of easily installed hardware and intuitive software.

CalAmp tracking devices for vehicles and assets alike are compatible with Actsoft solutions, making it easy for you to efficiently monitor your equipment and fleet cars. Help your team enhance accountability, safety, and savings through a combination of easily installed hardware and intuitive software. Our partnership with Uniden is ideal for companies looking to gain advanced diagnostics on their fleets. Uniden’s extensive product listing of car electronics like radios, dash cams, radar detectors, and in-vehicle communicators work in concert with Actsoft’s solutions to better connect your vehicles to the company headquarters.

Our partnership with Uniden is ideal for companies looking to gain advanced diagnostics on their fleets. Uniden’s extensive product listing of car electronics like radios, dash cams, radar detectors, and in-vehicle communicators work in concert with Actsoft’s solutions to better connect your vehicles to the company headquarters. Kyocera offers a wide range of mobile devices, ranging in design from traditional phones to ultra-durable handset technology. Actsoft is able to equip organizations in a variety of different industries with solutions for improved business, while Kyocera supplies the technology they can flawlessly operate on.

Kyocera offers a wide range of mobile devices, ranging in design from traditional phones to ultra-durable handset technology. Actsoft is able to equip organizations in a variety of different industries with solutions for improved business, while Kyocera supplies the technology they can flawlessly operate on.

Our software is the perfect complement to Apple’s user-friendly technology. Equip your workforce with the devices and solutions it needs for optimized productivity during daily operations with Apple and Actsoft.

Our software is the perfect complement to Apple’s user-friendly technology. Equip your workforce with the devices and solutions it needs for optimized productivity during daily operations with Apple and Actsoft.

Actsoft and Sanyo teamed up to merge intuitive business management software with the technology of today. This partnership allows us to provide you with all the tools your team needs for improved workflows, better coordination, and optimized productivity.

Actsoft and Sanyo teamed up to merge intuitive business management software with the technology of today. This partnership allows us to provide you with all the tools your team needs for improved workflows, better coordination, and optimized productivity. Motorola’s mobile technology works in tandem with our solutions to provide extra versatility to your business practices. Coupled with our software’s features, Motorola’s reliable devices make connecting your workforce simpler than ever to do.

Motorola’s mobile technology works in tandem with our solutions to provide extra versatility to your business practices. Coupled with our software’s features, Motorola’s reliable devices make connecting your workforce simpler than ever to do. We’re able to bundle certain solutions of ours (including our Electronic Visit Verification options) with Samsung devices to help your team achieve as much functionality as possible, while keeping rates affordable. Use these combinations for accurate recordkeeping, improved communication, and smarter data collection in the field.

We’re able to bundle certain solutions of ours (including our Electronic Visit Verification options) with Samsung devices to help your team achieve as much functionality as possible, while keeping rates affordable. Use these combinations for accurate recordkeeping, improved communication, and smarter data collection in the field.