Last week, we explored the management of the vehicles within your workforce. We primarily focused on the benefit that tracking your equipment provides against theft. While defending against theft is imperative, it is not the only way to manage the non-human components of your workforce.

Vehicles, in order to continue to contribute to your business effectively, require constant inspection and careful attention paid to how they are used. Vehicular management can present itself in the flavors of the maintenance of the vehicle’s parts to ensure it remains a part of the fleet and a detailed look at the vehicle’s fuel consumption to combat unnecessary expenses.

Maintenance

Your workforce is a machine, and for it to operate efficiently, it requires routine maintenance. Your vehicles are, literally, no different. While maintenance of vehicles is imperative, more often than not, people will address maintenance issues after they have arisen. Whether it be due to neglect or forgetfulness, this approach is reactive and can be detrimental to your equipment.

Once again, we look at Paul’s Pool Cleaning & Construction Company. Paul employs ten cleaners, each of whom drives one of the trucks in Paul’s fleet. Knowing that Paul has implemented dispatching, we can conclude that each of these ten workers completes six assignments each day. Each driver generates $600 per day and $3,000 per work week.

Now, let’s assume that Paul forgets to take two of his trucks in for their routine inspection. The result is a wrecked engine, requiring a full replacement. The cost incurred by each replacement is $3,000, but Paul’s business also suffers the loss of revenue generated by both vehicles. Had Paul invested in a software with a maintenance alert function, he could have been proactive about the care of his vehicles and potentially avoided the impact to his business.

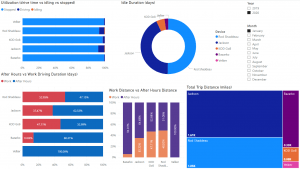

Idling Time

Maintaining the integrity of your fleet requires careful attention paid to the consumption of fuel by said fleet. Focusing on idling vehicles, trucks burn a gallon of fuel for every hour spent idling. With the average price of fuel in the United States being $2 per gallon, if Paul’s drivers left their vehicles on during every cleaning job, they would be idling for six hours per day.

52 Weeks/Year

X 5 Workdays/Week

260 Workdays/Year

X 6 Hours Idling/Day

1,560 Hours Idling/Year

X $2/Gallon of Gas

$3,120 of Fuel Spent Idling by Each Truck/Year

X 10 Trucks

$31,200 Fuel Spent Idling by the Fleet/Year

Potentially, Paul could spend over thirty thousand dollars on fuel just because vehicles were left running. Should Paul invest and install in software that relays whether the vehicle is turned off whenever it is stopped, he could save his company thousands of dollars in the years to come.

Utilizing software that allows you to stay on top of your vehicle maintenance as well as cut back on fuel consumption simply makes sense. With the streamlining of all of your business’s processes as the goal, you must take care to never forget about the vehicles in your fleet. Witness the immense returns after investing in the management of your fleet!

Have any questions on how Actsoft can help you?

Call (888) 732-6638 or Receive a Live Webinar

Encore & Geotab Drive

Encore & Geotab Drive

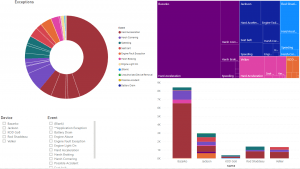

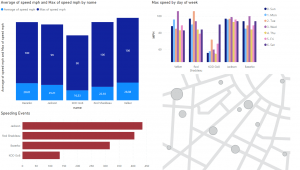

Gain even greater insight into the daily activities of your fleet using the combination of Geotab and Actsoft. Geotab devices provide detailed data collection and seamless integration with our solutions; learn more about the ways your vehicles are being used daily with the power of this tandem.

Gain even greater insight into the daily activities of your fleet using the combination of Geotab and Actsoft. Geotab devices provide detailed data collection and seamless integration with our solutions; learn more about the ways your vehicles are being used daily with the power of this tandem.

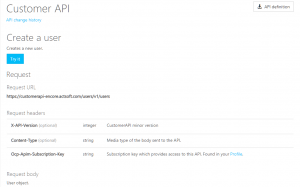

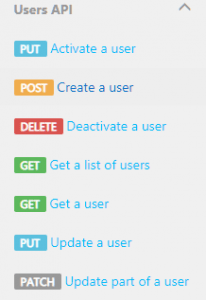

Actsoft partnered with Odin to provide our solutions overseas, through payment processing integrations. Odin helps us support user management for our software; customers can also purchase our products through Odin’s billing platform.

Actsoft partnered with Odin to provide our solutions overseas, through payment processing integrations. Odin helps us support user management for our software; customers can also purchase our products through Odin’s billing platform.

VisTracks powers our Electronic Logging Device (ELD) solution, which enables transportation businesses to easily automate their hours of service logs, remain in governmental compliance, and reduce their potential to incur costly fines.

VisTracks powers our Electronic Logging Device (ELD) solution, which enables transportation businesses to easily automate their hours of service logs, remain in governmental compliance, and reduce their potential to incur costly fines. Integration between Actsoft solutions and BeWhere’s software products is available. Take your team’s asset tracking, cellular data connectivity, and field insight a step further with effective, cross-application compatibility.

Integration between Actsoft solutions and BeWhere’s software products is available. Take your team’s asset tracking, cellular data connectivity, and field insight a step further with effective, cross-application compatibility.

CalAmp tracking devices for vehicles and assets alike are compatible with Actsoft solutions, making it easy for you to efficiently monitor your equipment and fleet cars. Help your team enhance accountability, safety, and savings through a combination of easily installed hardware and intuitive software.

CalAmp tracking devices for vehicles and assets alike are compatible with Actsoft solutions, making it easy for you to efficiently monitor your equipment and fleet cars. Help your team enhance accountability, safety, and savings through a combination of easily installed hardware and intuitive software. Our partnership with Uniden is ideal for companies looking to gain advanced diagnostics on their fleets. Uniden’s extensive product listing of car electronics like radios, dash cams, radar detectors, and in-vehicle communicators work in concert with Actsoft’s solutions to better connect your vehicles to the company headquarters.

Our partnership with Uniden is ideal for companies looking to gain advanced diagnostics on their fleets. Uniden’s extensive product listing of car electronics like radios, dash cams, radar detectors, and in-vehicle communicators work in concert with Actsoft’s solutions to better connect your vehicles to the company headquarters. Kyocera offers a wide range of mobile devices, ranging in design from traditional phones to ultra-durable handset technology. Actsoft is able to equip organizations in a variety of different industries with solutions for improved business, while Kyocera supplies the technology they can flawlessly operate on.

Kyocera offers a wide range of mobile devices, ranging in design from traditional phones to ultra-durable handset technology. Actsoft is able to equip organizations in a variety of different industries with solutions for improved business, while Kyocera supplies the technology they can flawlessly operate on.

Our software is the perfect complement to Apple’s user-friendly technology. Equip your workforce with the devices and solutions it needs for optimized productivity during daily operations with Apple and Actsoft.

Our software is the perfect complement to Apple’s user-friendly technology. Equip your workforce with the devices and solutions it needs for optimized productivity during daily operations with Apple and Actsoft.

Actsoft and Sanyo teamed up to merge intuitive business management software with the technology of today. This partnership allows us to provide you with all the tools your team needs for improved workflows, better coordination, and optimized productivity.

Actsoft and Sanyo teamed up to merge intuitive business management software with the technology of today. This partnership allows us to provide you with all the tools your team needs for improved workflows, better coordination, and optimized productivity. Motorola’s mobile technology works in tandem with our solutions to provide extra versatility to your business practices. Coupled with our software’s features, Motorola’s reliable devices make connecting your workforce simpler than ever to do.

Motorola’s mobile technology works in tandem with our solutions to provide extra versatility to your business practices. Coupled with our software’s features, Motorola’s reliable devices make connecting your workforce simpler than ever to do. We’re able to bundle certain solutions of ours (including our Electronic Visit Verification options) with Samsung devices to help your team achieve as much functionality as possible, while keeping rates affordable. Use these combinations for accurate recordkeeping, improved communication, and smarter data collection in the field.

We’re able to bundle certain solutions of ours (including our Electronic Visit Verification options) with Samsung devices to help your team achieve as much functionality as possible, while keeping rates affordable. Use these combinations for accurate recordkeeping, improved communication, and smarter data collection in the field.